We’re currently at the dawn of a new age of nostalgia in consumer electronics, from the return of vinyl record players to the latest classic gaming flash drives. More brands are following the footsteps of Nintendo and Nokia and resurrecting their old products whilst at the same time selling new and modern ones. But it’s not about making a profit of our fond memories.

People are increasingly attracted by the beauty, elegance and simplicity of classic designs. In fact, one of the biggest trends sees younger generations turning their backs on high-tech smartphones in favour of ‘dumb’ models from the 1990s. The come-back of a humble foldable phone is being driven by a nostalgic craze for 90s retro together with a desire to switch off from the always-on experience of the latest smartphones. This leap forward in the design of consumer electronics means manufacturers and designers are now challenged to offer greater flexibility whilst at the same make products more reliable and durable.

Design freedom is an urgent necessity but how do you achieve it?

The growing popularity of retro look flip-phones, in particular, highlights the need for creative freedom as designers create these latest classic look gadgets. Old-ish designs are often complex to generate as they have multiple moving parts. When opting in for a foldable phone, consumers don’t want to go down the memory lane of frustrating glitches but rather the easiness and simplicity of making and ending calls just by opening and closing the phone. This requires the devices to be high-quality in design. Yet they still need quality protection – not least from the possibility of liquid ingress.

Consumers have come to expect this capability today as they want their devices to last as long as possible. If you were to buy any of the leading flagship phone products, they would all have a level of liquid protection. Frankly, the good old Nokia 3310 is still claiming the top spot of an indestructible phone today, even when dropped on a pavement it would more often than not still be working perfectly fine. Designers must find a way of building this capability into modern devices that are exposed to threats 24/7 without compromising the look feel and flexibility of the device in any way.

Ensuring quality by getting liquid protection right

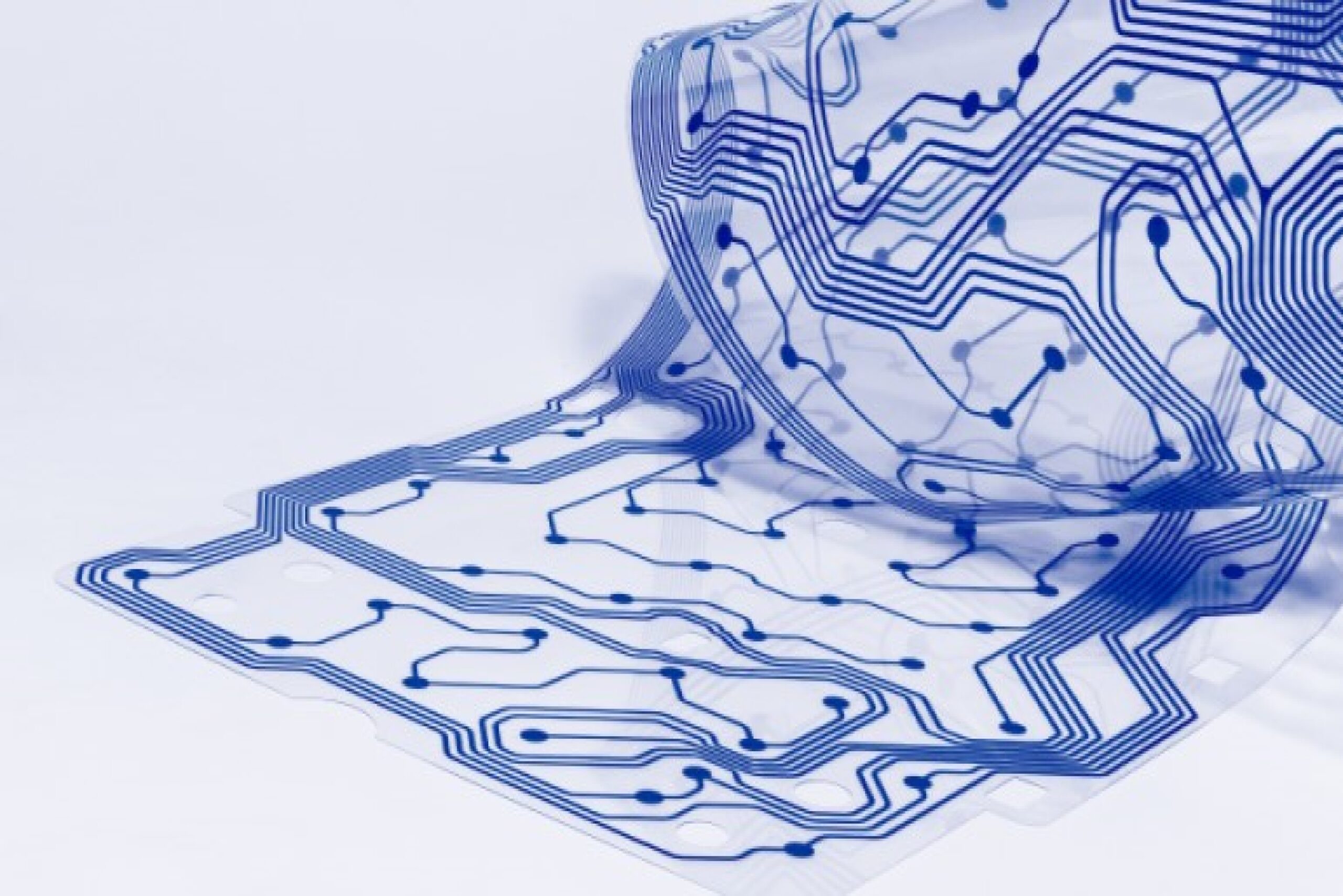

As a designer, you may have achieved a bigger screen and battery but you still have to design in your ‘standard’ features, including liquid protection. In today’s world of carrying devices around 24/7, there is a greater demand for liquid protection going beyond just splashes and spills, and now requiring protection to harsh environmental threats, post dropping and outer casing damage. The difficulty of traditional mechanical seal solutions for liquid protection is they are not designed to be flexed or bent in any way. That’s why they are used to seal rigid devices rather than devices with folding screens. If used on the latter, mechanical seals become quickly damaged and cease to protect the device from liquid entering and harming the internal electronics.

Ultra-thin plasma coatings, in contrast, allow for this movement and are not compromised over time. P2i’s end-to-end water protection solution Barrier Coating requires no seals or gaskets and provides manufacturers with the opportunity to go beyond the traditional device design, including foldable and flexible displays and bezel-less designs. The protection of internal components ensures that water can repeatedly enter the device without the risk of liquid damage, allowing consumers to love their retro devices for longer.

New philosophy for innovative retro design

In creating electronic devices, manufacturers must have design freedom to meet the changing consumer trends and high expectations, as well as immerse themselves in the creativity that the design field is all about. This freedom and flexibility becomes more important the more the design differs from a standard format and the more movable parts it has. Manufacturers should never be constrained by components and technology being added to their product. That’s core to the ethos of electronic product design and should be a priority for any electronic products manufacturer, choosing what solutions to add to their devices.

If you’re interested in finding out more about how nanotechnology liquid protection solutions can enable you to embrace and benefit from greater design flexibility, check out P2i’s range of solutions here.